DISCOVER OUR RANGE OF SERVICES

Our services

What we do

Component manufacturing

We manufacture components for our customers based on samples, customer drawings or CAD files. We have modern machinery that allows us to manufacture components quickly and precisely. Our services include jig construction, individual one-off production, component assembly as well as series and spare parts production.

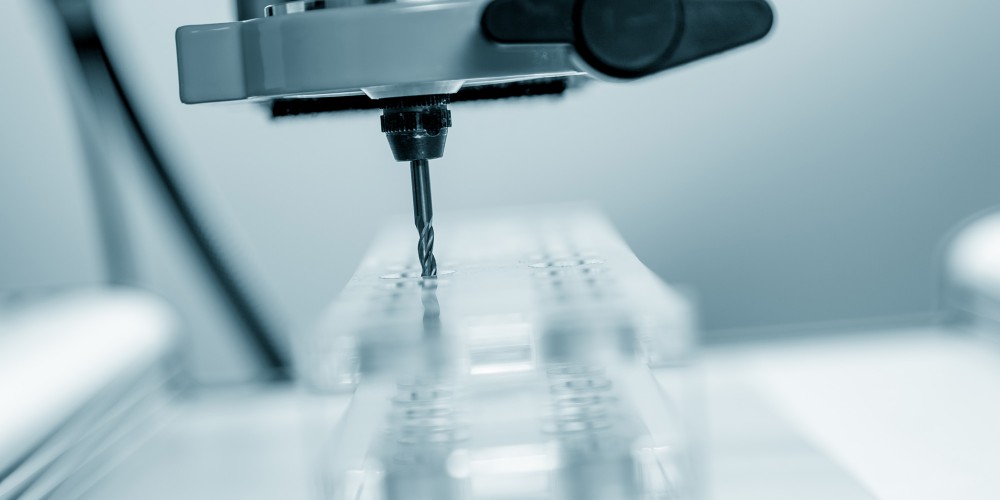

CNC area

Our range of services includes turning work, but also milling work, CNC turning and CNC milling. We carry out the turning and milling work on time, precisely and inexpensively. Our product range extends from complex individual parts to standardized mass-produced parts.

Materials

We process construction, tempering, free cutting, case-hardening and tool steel, rust and acid-resistant steel and non-ferrous metals such as plastic, copper, aluminum, titanium and titanium alloys. Various special materials are also possible on request at any time.

Further processing

Thanks to close cooperation with reliable partners, we are able to offer our customers various further processing methods such as grinding, honing, deep-hole drilling, balancing and all heat and surface treatments.

The range of services

Our customers benefit from our extensive range of services. In addition to the CNC area, we are also able to offer component production and the further processing of numerous materials. Whether high-precision turning and milling technology, the manufacture of components according to customer drawings or the processing of a wide variety of materials, the needs of our customers are always the focus.

We would be happy to conduct a consultation with you in advance so that we can go into detail about your wishes and needs. You will then receive a free and non-binding offer from us, on the basis of which you can make an informed decision.

Modern CNC technology

We have modern CNC machines that are available in our specialist company in Hildesheim. We use CNC milling technology and CNC turning technology to manufacture components for you. We carry out all work punctually, precisely and inexpensively and place the satisfaction of our customers at the center of our work. CNC machines are machine tools that are capable of automatically producing workpieces with high precision. They surpass mechanically controlled machines in terms of precision and speed.

When working with the machines, we use a CAM system that can read data from a CAD program into the machine. As a rule, the components that our customers order are created with a CAD program. When reading in, we take into account factors such as the geometry of the tools, speeds and feeds in order to guarantee precise production.

Präzise Fertigung nach Maß

GEBU-tec GmbH manufactures high-precision CNC turned and milled parts for different industries and requirements.

By manufacturing with modern CNC-controlled lathes supplemented by the use of machining centers, conventional and special machines, we can cover the largest possible machining area.

We turn from the bar up to Ø 60 mm and in the jaw chuck up to Ø 400 mm. In addition to milling complex workpieces “from the solid”, we also process raw parts, profiles and formed parts as well as cast quickly and efficiently. The 3-D programming system vectorcam with CAD/CAM interface enables the program creation and processing of existing drawing data.

To ensure our claim to quality and innovation, we continuously invest in our machinery and the training of our employees.

Machine parameters

Hyperturn 45

- Siemens One control

- Main and counter spindle (max. ø42)

- 2x tool turrets

- 24x driven tools

Arrival and commissioning of our new Hyperturn 45

With this investment, we are further modernizing and expanding our machinery in order to be well positioned for new challenges and requirements.

New machine: Emcoturn Maxxturn 95

Arrival and commissioning of our new EMCO MAXXTURN 95:

- Siemens One control

- Max. turning diameter 350 (three-jaw chuck)

- Max. turning length 1400mm

- Steady rest and tailstock

- 12x driven tools and Y-axis

Change of management at Gebu-tec GmbH

Jan Geburek has taken over the management position at Gebu-tec GmbH, replacing Lutz Schünemann.

CNC universal lathe

- Machining dimensions: Ø45 mm x 510 mm

- Servo turret with driven tools

- Y axis

- Direct, absolute displacement measurement

- Short bar feeder

CNC universal lathe

- Machining dimensions: Ø65 mm x 510 mm

- Servo turret with driven tools

- Direct, absolute displacement measurement

- Short bar feeder

CNC universal lathe

- Machining dimensions: Ø400 mm x 1,000 mm

- Spindle bore: 76 mm

- Spindle diameter in front bearing: 105 mm

- Servo turret

- Bezel: Ø40mm – 240mm

CNC universal lathe

- Machining dimensions: Ø300 mm x 655 mm

- Spindle Bore: 52mm

- Servo turret

Universal cycle lathe

- Processing dimensions: Ø360 mm x 1,300 mm

- Bezel

Location

GEBU-tec GmbH

Dornierstraße 10

31137 Hildesheim

Contact

- info@gebu-tec.de

0049 05121-510970